Introduction of toughened cold resistant nylon PA6

When the word nylon is mentioned to the general people will think of clothing fabrics and other textiles, which is one of the big uses of nylon. However, for nylon injection molding manufacturers, nylon two words represent another meaning, that is, materials, material, to injection some parts of the first thing to do is to identify material. Toughened and cold-resistant nylon 6 material is a common material designed for low temperature environment. It can still be used in -40℃ environment.

Compared with general plastics, nylon has the advantages of wear resistance, toughness, oil resistance, corrosion resistance and easy molding, and occupies a place in the plastic products industry. However, plastic has a common character in low temperature environment, that is to become brittle, gently fall on the broken, corresponding products can not play its real role, big "Jiong" written on the face. Facing this dilemma, Linyuan modified nylon factory produced toughened nylon 6 material. Materials or products in low temperature environment are faced with the problem of brittleness. No matter how good the material is, it cannot show its glorious side. The solution of brittleness is to improve toughness and impact strength, toughened nylon 6 material is just suitable.

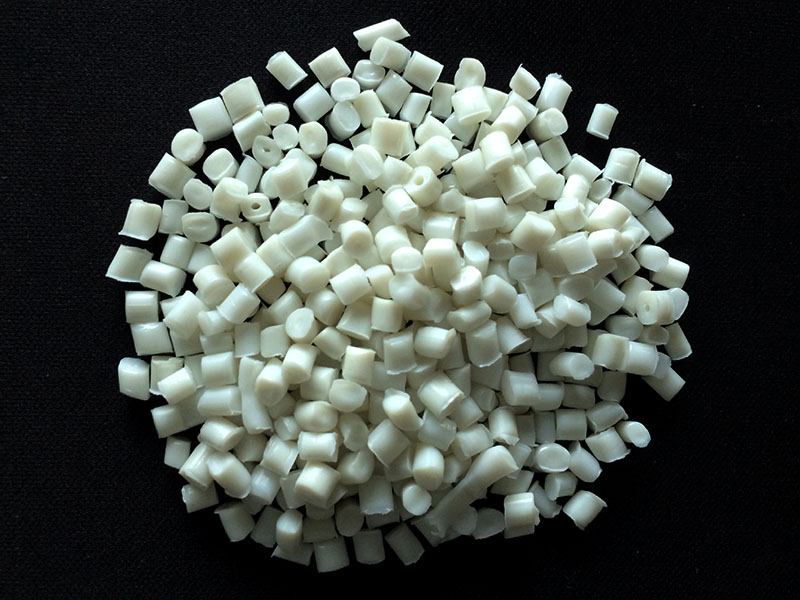

The material uses special toughening agent, weighing a certain ratio added to nylon material, mixed with other additives, after a special extruder 200-250℃ melting, mixing, extrusion, wire drawing, granulation, so as to get toughened PA6 material.

The leading role of the magic effect of -40℃ is toughening agent, commonly used toughening agent maleic anhydride graft POE, EPDM, EVA, etc., mainly introduces the contribution of EVA to the material. EVA is one of the more common thermoplastics at present, and its performance is related to the content of VA in vinyl acetate.

In order to improve its impact, absorb the impact energy, chooses the material toughening materials need to consider the elastic differences, nylon and toughening material composition or polarity parameters between the modulus of elasticity is larger, general selection of non-polar olefin elastomer, in order to make materials and toughened pa6 toughening agent has certain compatibility and interface binding force, grafting is necessary, By grafting reaction, two incompatible materials can be closely combined to achieve twice the result with half the effort.

If toughened low temperature resistance nylon 6 material just has toughness advantage that is very wrong, it has inherited nylon 6 itself with high strength, in the case of good toughness in strength can still sling ordinary plastics such as PP, PE, etc., it can be competent for high strength operation in ultra-low temperature environment.